Technologies

exceptional results.

Flexo Labels

We offer a wide range of premium finishes.

Our techniques include hot foil, cold foil, embossing, micro-embossing, debossing, serigraphy and silkscreen printing, each adding a unique visual and tactile aspect that is essential for impactful branding.

These techniques do more than enhance the aesthetics of the labels, they also provide remarkable tactile quality, amplifying the consumer’s brand experience. They are ideal for clients who want to stand out in the market with strong branding.

Categories

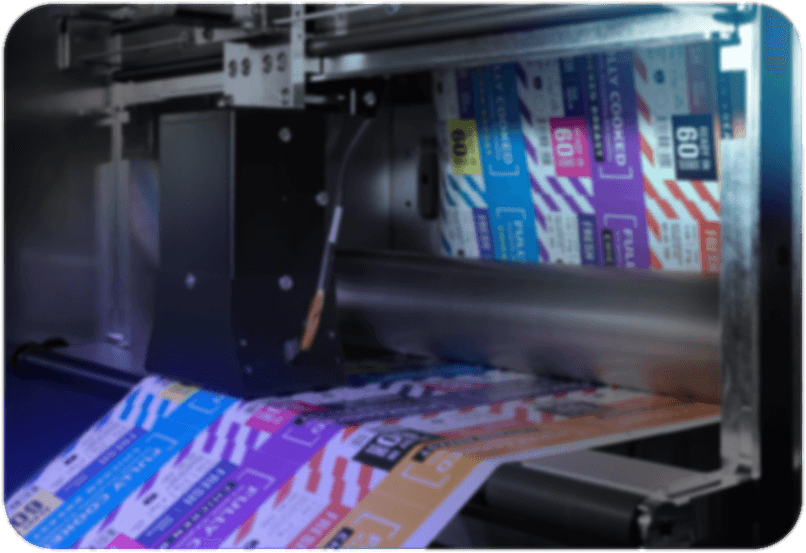

We utilize state-of-the-art digital equipment for label production, offering real-time customization and vibrant colors, ideal for short to medium runs.

Flexographic printing machines allow for printing on a variety of materials, including paper, plastic, and other flexible substrates, with high quality and efficiency for large runs.

Embossing and Debossing – This technology creates tactile effects on labels using custom dies to achieve precise and refined relief details.

We own specialized equipment for applying metallic foil, both hot foil and cold foil, a procedure that offers our labels a shiny and premium effect

Automated die-cutting equipment enables the cutting of labels into complex and precise shapes, regardless of size or complexity, with minimum waste.

We use UV coating technology for protection and visual effects, along with laminating equipment to safeguard labels against wear and tear.

Custom shapes for labels are created using high-precision die-cutting machines.

We employ integrated automatic monitoring systems to ensure the consistency and quality of each produced label, reducing errors and maintaining high standards.

At FLEXO, we combine cutting-edge technologies with high-quality consulting services to ensure that every label project exceeds expectations. Through close collaboration with our clients, we provide customized solutions that perfectly blend technological innovation with a focus on each brand’s specific needs:

- Customized consulting: We analyze the needs and goals of each client to offer technical and creative solutions that align perfectly with their vision.

- Optimal technology selection: We choose the most suitable printing and finishing technologies to ensure a high-quality result, tailored to the specifications of each project.

- Technology integration: We combine advanced techniques such as hot foil, embossing, and digital printing to create unique labels that stand out in the market.

- Continuous support: We provide technical support and consulting throughout the entire process, from concept to execution, ensuring that the final result is exactly what the client desires.

- Innovation and adaptability: We stay updated with the latest trends and technologies, ensuring we provide innovative and efficient solutions that contribute to the long-term success of brands.